Cleaning carpets from industrial oils is a difficult issue that professionals constantly have to face, as industrial carpet holds a persistent mix of oily and adhesive soils that bond tightly to fibres.

Motor oils, greases, waxes, resins, bitumen, tar, and factory fallout repel water and require controlled alkaline chemistry to break their grip without compromising the stain-resistant treatments of 5th and 6th-generation nylon. A low-residue, mildly alkaline encapsulation detergent provides the best balance of safety and cleaning performance.

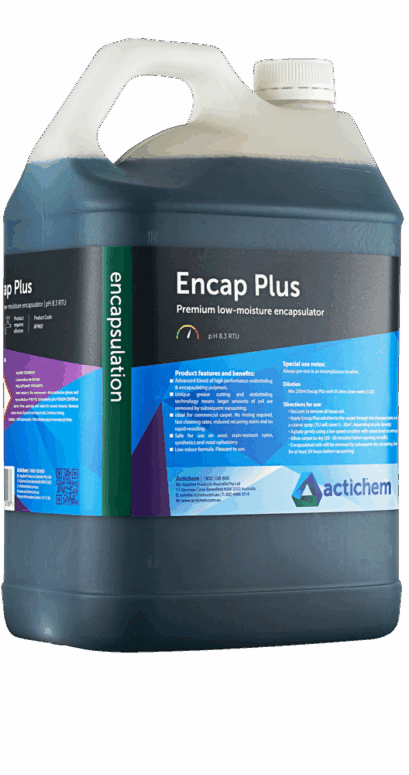

How Encapsulation Ensures Clean Carpets.

Encapsulation works particularly well in industrial sites because it delivers strong soil release while keeping moisture levels low. Encap Plus dissolves oily contamination, suspends the loosened soil, and surrounds it with a polymer film that dries to a brittle structure. This structure fractures during the next vacuum cycle, carrying away both soil and detergent residues and preventing rapid resoiling. The method supports fast drying, minimal disruption, and clean presentation across large areas.

Low moisture encapsulation detergent

Dilute 1:32 (30ml per 1L)

Encap Plus dissolves oily residues, softens adhesive films, and encapsulates loosened contamination for removal during post-vacuuming. Its polymer system prevents re-deposition, and its controlled alkalinity protects stain-resistant fibre treatments.

Important Note

Cleaning 5th & 6th Generation Nylon, Polyester, Acrylic Carpets

When cleaning 5th and 6th-generation nylon, polyester, and acrylic carpets, do not use products with a pH level higher than 10. Using such products can damage the stain-resistant properties of these carpets.

Equipment

- Rotary or oscillating pad machine

Provides the agitation needed to break oily soil bonds and distribute the polymer. - Pump-up sprayer or onboard solution tank

Ensures even and consistent application of Encap Plus. - Vacuum with power head or brush

Essential before and after cleaning for maximum soil recovery. - Air movers or ventilation

Used to accelerate drying and keep downtime low. - PPE

Required when handling detergents and when working around petroleum-based soiling.

The Process

-

Pre-Vacuum

Remove as much dry particulate as possible. Factory carpets accumulate fine dust that binds to oily residues, reducing cleaning efficiency if not removed first.

-

Prespray

Apply Encap Plus diluted 1:32 using a sprayer or the scrubber’s tank. Aim for even coverage with enough solution to support visible foam during agitation.

-

Agitate

Work the carpet using a rotary or oscillating pad machine with overlapping passes. Agitation breaks the bond between petroleum residues and fibres and activates the encapsulation chemistry

-

Drying

Allow the carpet to dry for roughly 40–60 minutes. Support airflow through fans or air conditioning in large sites to maintain quick turnaround.

-

Post-Vacuum

Vacuum after 24 hours to remove the dried polymer crystals and encapsulated soil. Power-head vacuums achieve the strongest recovery.

Further Notes

-

Booster for Severe Petroleum Spots - Citrus Gel

For concentrated bitumen, tar, resin, or heavy grease deposits. Apply sparingly and blot. Rinse lightly before proceeding with the VLM clean.

-

Encapsulation Spotting Options

Conquer

For general oily and water-based spotting.Conquer O2

For stains that require brightening or added sanitising power.

Where To Buy

Encap Plus

Low moisture carpet cleaning detergent

Low moisture carpet cleaning detergent

Find a Stockist